In a question and answer interview with Gulf Times, Boeing said, “As Qatar and the broader region have emerged as major hubs for air travel and cargo shipments, the need for safety, sustainability, efficiency and reliability in aviation becomes increasingly crucial. By strategically investing in automation and digital tools, GCC countries can unlock significant opportunities to enhance their aviation capabilities.”

Digital solutions and automation can lead to meaningful gains in airworthiness, operational efficiency, affordability and sustainability in maintaining and operating commercial and defense fleets, it said.

Moreover, transformational technologies play a significant role in upskilling the local workforce, nurturing talent, and encouraging research and development.

By collaborating with companies like Boeing, academic institutions and non-profit organisations in the GCC can empower students to participate in the development of cutting-edge technologies. “Investing in automation and digitalisation will not only advance the aviation sector but also foster economic growth and transition to a knowledge-based economy in Qatar and other GCC countries,” Boeing noted.

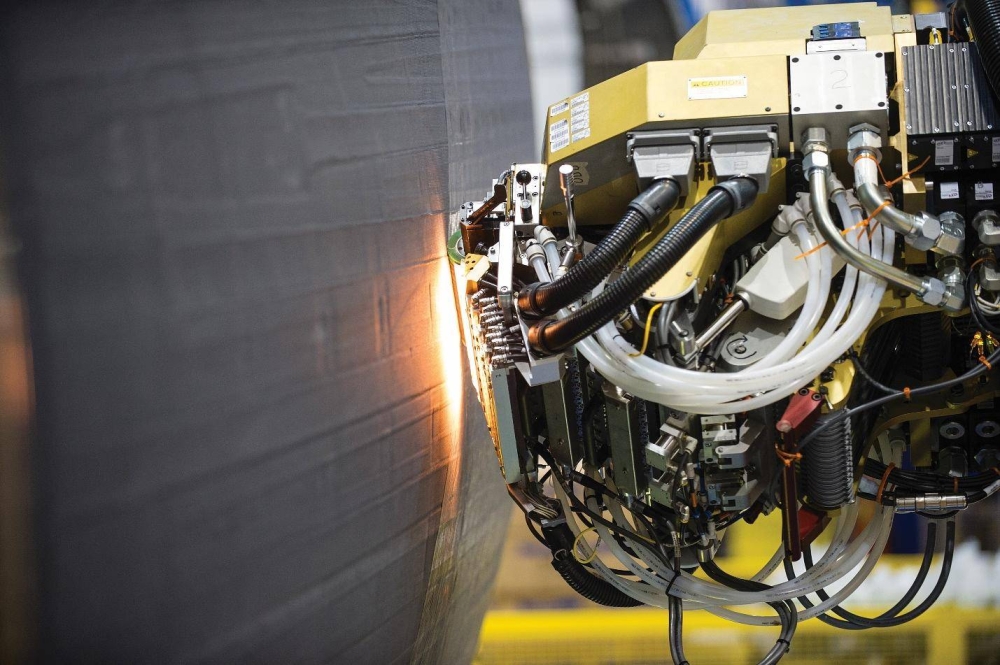

Robotics are providing the workforce with tools to do complex or physically demanding jobs in a way that is better for the wellbeing of people.

“We continue to evaluate future applications that will further enhance the safety of our team members and allow them to meet exacting requirement and produce the highest quality products,” Boeing said.

Highlighting the impact of robotics on the aviation industry in general, Boeing said, “Robotics plays an important role in aerospace. The industry is undergoing a significant transformation through automation and digital innovation, with robotics impacting different areas from design to production, operations, maintenance and training.”

- Design: New technologies like digital twins and model-based systems engineering have revolutionised aircraft design.

- Manufacturing: Robotics integration is improving workplace safety.

- Operations: Digital solutions combine data analysis and engineering know-how to enable lifecycle opportunities for customers, technicians and maintainers. They can help operators decrease costs, fuel consumption and associated carbon emissions while maintaining fleet readiness and performance.

- Maintenance: Autonomous systems like drones can be part of enhanced maintenance practices, allowing for more accurate and efficient aircraft inspections. Additionally, predictive maintenance digital tools can anticipate when and where parts are needed and decrease downtime.

- Training: Virtual reality technologies are revolutionising aircrew training and are tested in the defense sector.